Researchers in McGill’s Biomass Production Laboratory are improving local, indoor food production methods to increase access to fresh produce year-round

“Local” may be a buzzword of the modern food movement but it is not a new concept: for most of human history, food simply was local.

“The historical solution for food has always been, individuals grow, or hunt and gather, their own food for their own consumption,” says Mark Lefsrud, an associate professor of bioresource engineering in McGill’s Faculty of Agricultural and Environmental Sciences (AES).

Since the end of World War II, however, “we’ve moved away from that,” says Lefsrud. Today, “about five percent of the world’s population is supplying 95% of the world with their food source. The difficulty is we have zero resilience when that happens.”

The impacts of climate change, rising fuel costs, geopolitical conflicts, and global supply chain snags make this system – and the 8 billion people who depend on it – increasingly vulnerable.

Part of the solution to building a more sustainable and resilient agrifood system, says Lefsrud, is to increase local, indoor food production – which can extend local growing seasons and improve access to fresh produce.

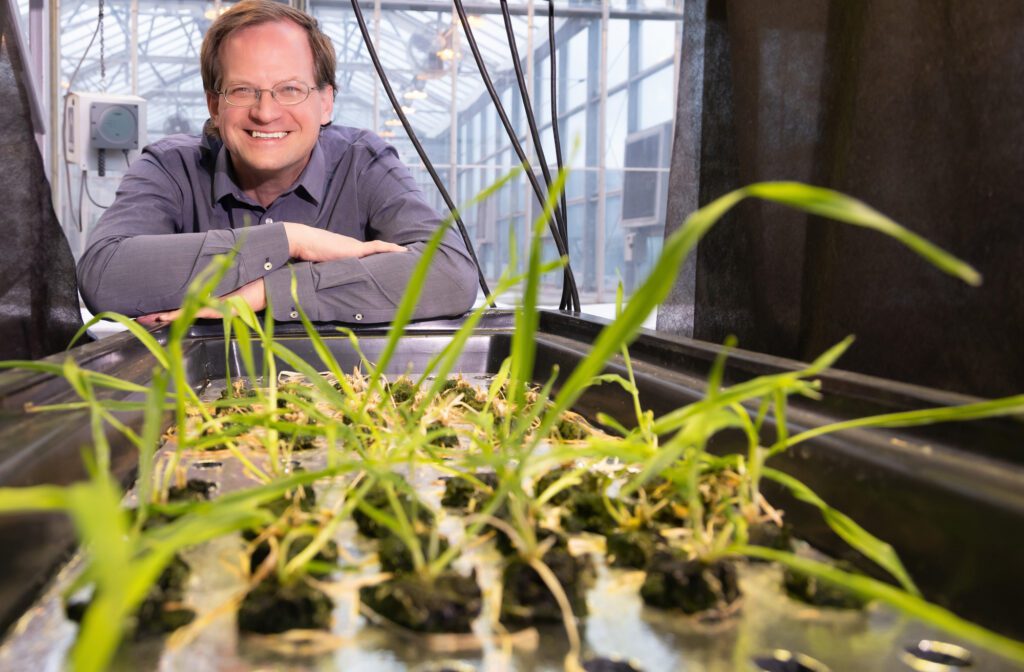

Lefsrud leads McGill’s Biomass Production Laboratory, part of a constellation of AES initiatives – including the renowned Margaret A. Gilliam Institute for Global Food Security – focused on tackling the twin challenges of sustainable agriculture and food security. Together, these initiatives make up the Smart Agrifood Hub, a major fundraising priority for AES that aims to accelerate discovery and translate innovative practices and technologies from the lab to the field, farm, or table.

Ultimately, the goal is to produce about one percent of the total lettuce consumed in Canada. If you could get to 10 per cent, now you are supplying lettuce to all of Montreal.”

Mark Lefsrud

“Our goal as a sustainability effort is to try to return some food productivity back to the local areas,” says Lefsrud, an expert in controlled environment agriculture

In particular, Lefsrud points to seasonal food gaps and food deserts – which can be inner-city neighbourhoods or remote, rural locations, anywhere in the world, where fresh produce is not easily accessible – as areas where this approach can be a gamechanger.

Extending Canada’s short growing season, for example, would make it possible for Montreal to supply more of its own fruits and vegetables over the course of the year.

Leafy green vegetables and fruits such as strawberries and raspberries could potentially be produced locally year-round, for example, while growing seasons for things like corn could stretch to three or four months.

“Ultimately,” says Lefsrud, “the goal is to produce about one percent of the total lettuce consumed in Canada. If you could get to 10 percent, now you’re supplying lettuce to all of Montreal.”

Growing more nutritious food, faster

Researchers and students in the Biomass Production Laboratory are working on enhancing controlled environments to make this scale of indoor food production more efficient and to improve the nutritional quality of food produced.

Controlled environment agriculture can include any kind of enclosed or indoor growing environment where growers regulate the environmental factors that influence plant growth, such as temperature, humidity, carbon dioxide (CO2) levels, light levels and nutrient systems.

One of the Lab’s major research projects involves looking at how plants respond to changes in light sources.

In recent years, LED light has become the preferred source for controlled growing environments, replacing traditional broad-spectrum light systems. But LED lights are very narrow spectrum: a red LED, for example, is basically red, with few other wavelengths. Lefsrud and his team want to understand how that shift affects a plant’s growth.

“What happens to the plant if I provide a narrow spectrum of light? Is it going to get shorter or taller, is it going to produce more fruit or less fruit?” asks Lefsrud. “A fair bit of our work is trying to figure these things out.”

The results have been promising. Using narrow wavelengths, the team has observed faster plant growth – in some cases double the speed of growth under traditional systems.

The team also uses CO2 enrichment, which requires less water usage and fertilizer, to speed up plant growth.

“One of the great ironies is that climate change is good for plants,” says Lefsrud. “Plants don’t like CO2 levels where they are right now, which is about 400 parts per million. In controlled environments, we try to enrich to 750 to 1500 parts per million. Instead of venting CO2 into the atmosphere, we vent it into the greenhouse, and we can get these faster growth rates.”

The Lab is also exploring how manipulating light and nutrient systems can improve plants’ nutritional density.

Certain wavelengths can, for example, make a plant’s leaves dark purple or almost black – a change which indicates the plant is producing a lot of antioxidant-rich anthocyanins, the pigments responsible for producing the red, blue and purple colours of fruits and vegetables.

Likewise, by adjusting the fertilizers, microorganisms, or plant hormones they feed to plants’ root systems, researchers can accelerate growth and push most plants to start accumulating more nutrients such as vitamins or calcium.

Kale – already widely regarded as a “superfood” for its high nutritional value – has a calcium content on par with cow’s milk. But by changing the light source or nutrients within the root zone, Lefsrud and his team have been able to increase the calcium accumulation by two or even three times the usual amount, far exceeding the calcium found in cow’s milk, and in a more highly bioavailable form.

“It almost becomes like a vitamin pill as a leaf of lettuce,” says Lefsrud.

Using tech to create the perfect growing conditions

The Lab uses plant sensors, machine vision systems, AI technology and Raspberry Pi microprocessors to observe these changes in the plants and their environment and track them in real time.

Automatic systems – the holy grail of controlled environment agriculture – regulate environmental factors affecting plant growth, allowing growers to maintain perfect growing conditions at all times.

“I’ve always been really passionate about technology and coding,” says Robinson Cayre, a fourth-year bioresource engineering student. “Controlled environments combine both, the farming aspect and growing plants as well as the technology involved in it. That’s what I love the most.”

Cayre interned in Lefsrud’s lab last summer, thanks to funding from the Alton and Dianne McEwen and Family Internship Program, which provides support for experiential learning opportunities for AES students. It proved a pivotal experience for Cayre, who missed out on other opportunities for hands-on learning because of the pandemic.

“The internship was great because it was very self-directed, and I learned a lot. I actually touched things and experimented, which is a hundred times better than just reading slides,” says Cayre, who was one of 26 students to receive McEwen Internship funds last year. “I ended up really being passionate about microcontrollers and what they can do. I am doing all my projects with sensors now and connecting them to the internet. I feel like I’m getting better every time I do something new.”

Armed with this experience, Cayre is now developing his own automatic system for mushroom farming for his Senior Design project. He and his classmates are building a grow box, paired with a web app, to regulate environmental factors like humidity, temperature, and CO2 levels. If successful, the system could be a disruptor in mushroom farming, which remains a very manual practice.

“Tech and food security go together nowadays,” says Cayre, who aims to continue working with AI monitoring systems in the field after graduation. “Autoregulation can save a lot of time for farmers and maximize yields. It’s really important to develop these technologies and bring something new to the market.”